The Role of Lightweight Composites in Modern Building

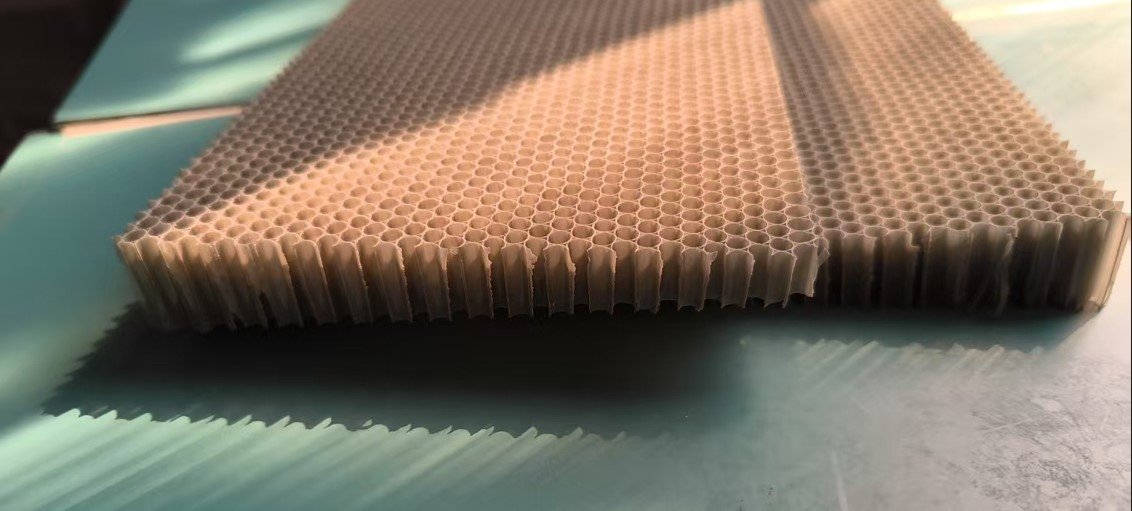

The global construction industry is rapidly adopting lightweight composite materials to meet demanding standards for energy efficiency, ease of installation, and structural performance. Plastic honeycomb panels are emerging as a prime alternative to traditional heavy materials, offering an unparalleled strength-to-weight ratio. For industrial buyers and development units, understanding the specific thermoplastic used in the core is key to optimising project outcomes.

Key Plastic Honeycomb Types for Architecture

While various plastics are utilised, the construction sector primarily relies on two types of thermoplastic honeycomb cores—Polypropylene (PP) and Polycarbonate (PC)—each tailored for distinct applications:

Polypropylene (PP) Honeycomb Core: This is the most prevalent choice for structural and high-moisture applications. PP cores are prized for their superior chemical and water resistance, making them impervious to rot, mould, and corrosion. In construction, PP honeycomb panels are widely used for:

l Subflooring and Raised Floors: Offering high load-bearing capacity with minimal weight, reducing structural load.

l Lightweight Partition Walls and Modular Structures: Accelerating on-site construction timelines.

l Marine and Wet Area Applications: Ideal for shower panels, bathroom partitions, and floating structures due to excellent moisture resistance.

Polycarbonate (PC) Honeycomb Core: PC is known for its outstanding impact strength and high-temperature resistance, often incorporating UV stabilisers. Its unique property is light transmission, making it highly valuable for specific architectural features:

l Light-Transmitting Panels and Skylights: Used in transparent or translucent sandwich panels where natural light diffusion is desired without compromising insulation.

l Architectural Cladding and Facades: Providing durable, rigid exterior elements with enhanced hail and impact protection.

l Air flow diffuser: Use a uniform honeycomb structure to deliver stable, draft-free ventilation. They are lightweight, corrosion-resistant, and easy to clean.

Core Benefits for Industrial Buyers

Specifying the correct plastic honeycomb ensures project success. By choosing our PP and PC core panels, industrial partners gain:

l Logistical Efficiency: Drastically reduced material weight leads to lower transportation costs and simpler, faster on-site handling.

l Long-Term Durability: Resistance to environmental factors (moisture, chemicals, temperature) guarantees a longer service life and reduced maintenance.

l Enhanced Insulation: The cell structure provides excellent thermal and acoustic damping, contributing to LEED certification goals and occupant comfort.

Our technical team is ready to assist you in selecting the optimal cell size, density, and skin material (such as FRP, HPL, or aluminum) to meet your project's precise structural and aesthetic specifications.

Qingdao Achieving Honeycomb – Your Trusted Partner in Honeycomb Core Solutions

With nearly two decades of manufacturing expertise, Qingdao Achieving is a leader in the honeycomb core industry. We are committed to meeting customised client needs at our core, continuously refining our self-developed equipment, and enhancing product quality to ensure every honeycomb panel delivers exceptional and consistent performance.

Standard Product Specifications:

PP (Polypropylene) Honeycomb Core: Standard colour is white. Common cell sizes include 6mm, 8mm, and 10mm. Thickness ranges from 2mm to 200mm, available for customisation.

PC (Polycarbonate) Honeycomb Core: Available in transparent, black, and grey. Common cell sizes include 3.5mm, 6mm, and 8mm. Thickness ranges from 5mm to 500mm, available for customisation.

Standard Panel Size: 1220 x 2440 mm. Complimentary cutting services are available.

PP and PC are renowned for their excellent formability and comprehensive properties, making them among the most mainstream raw materials for high-performance honeycomb panels today.

Choosing Qingdao Achieving means partnering with a reliable expert dedicated to turning innovative, lightweight, high-strength, and durable designs into reality, helping you gain a competitive edge in the marketplace.