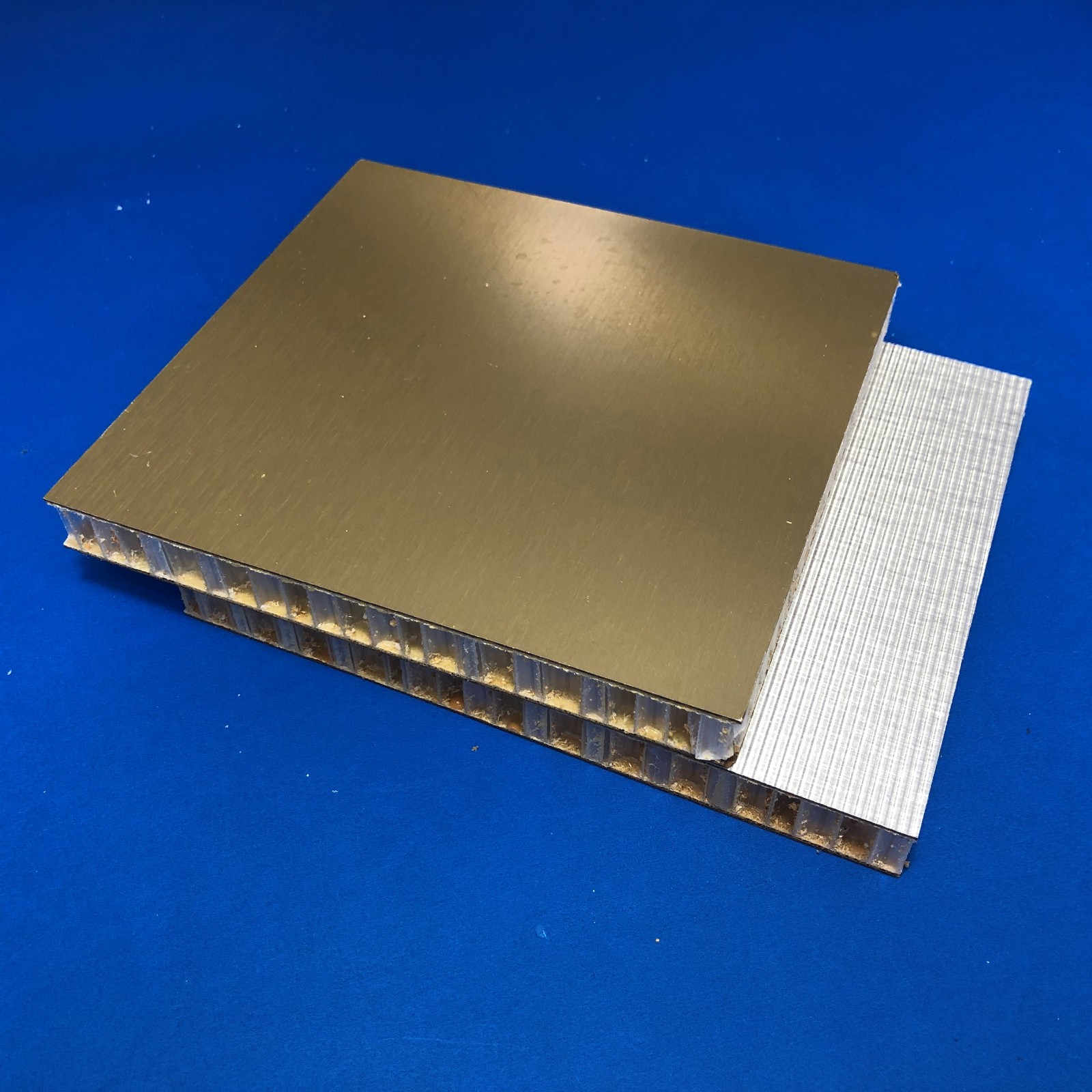

The Composite Panel: A System Engineered for Performance

A plastic honeycomb panel is only as effective as the material it is bonded to. In a composite sandwich structure, the facing sheets (skins) bear the tension and compression forces, translating the low-density core's stability into true structural strength. For industrial applications, selecting the correct skin material is paramount for durability, aesthetics, and specific functional requirements (e.g., UV resistance, scratch resistance, or fire rating).

The Most Common Industrial Facing Materials

Our Polypropylene (PP) and Polycarbonate (PC) honeycomb cores are engineered for superior adhesion to a wide range of high-performance skin materials:

l Fiber-Reinforced Plastic (FRP) / Glass Reinforced Plastic (GRP):

Advantage: FRP is exceptionally robust, corrosion-resistant, and offers excellent flexural strength. FRP skins are the industry standard for truck bodies, refrigerated vans, and marine bulkheads due to their moisture resistance and easy-to-clean gel-coat finish.

Application Focus: Logistics and Transportation, where seamless, durable surfaces are required.

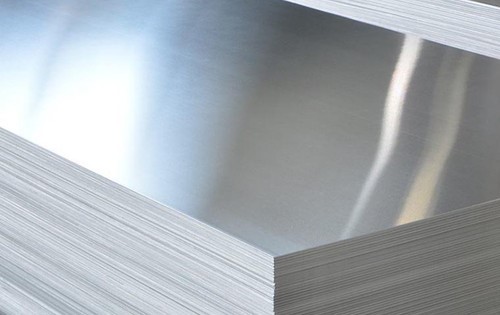

l Aluminum Sheets:

Advantage: Aluminum skins provide maximum rigidity, superior impact resistance, and a premium aesthetic finish. When combined with a lightweight PP core, the panel achieves mechanical properties often superior to solid aluminum.

Application Focus: Architectural facades, cleanroom construction, and sophisticated rail interiors where rigidity and a metallic look are essential.

l Continuous Fiber Reinforced Thermoplastic (CFRT):

Advantage: CFRT skins, made from materials like continuous glass fiber reinforced PP, offer a fully recyclable, high-strength solution. These skins are thermally fused directly to the PP core, eliminating the need for adhesives and creating an incredibly strong, mono-material composite.

Application Focus: Automotive underbody panels, EV battery casings, and high-volume,

cost-sensitive applications requiring superior environmental credentials.

l High-Pressure Laminates (HPL) / Vinyl / Wood Veneers:

Advantage: These decorative skins are chosen when the panel serves an interior, non-structural function, such as furniture, office partitions, or mobile home interiors. They provide aesthetic versatility while still benefiting from the lightweight core.

Application Focus: Interior design, office furniture, and specialized recreational vehicles (RVs).

Selecting the Optimal Composite

The final performance of the panel is a synergy of the core and the skin. We work with our industrial partners to determine the ideal combination, factoring in shear modulus, compressive strength, adhesion compatibility, and the intended operating environment. This customization ensures that your lightweight composite solution delivers maximum ROI and technical reliability.

Qingdao Achieving Honeycomb – Your Trusted Partner in Honeycomb Core Solutions

With nearly two decades of manufacturing expertise, Qingdao Achieving is a leader in the honeycomb core industry. We are committed to meeting customized client needs at our core, continuously refining our self-developed equipment, and enhancing product quality to ensure every honeycomb panel delivers exceptional and consistent performance.

Standard Product Specifications:

PP (Polypropylene) Honeycomb Core: Standard color is white. Common cell sizes include 6mm, 8mm, and 10mm. Thickness ranges from 2mm to 200mm, available for customization.

PC (Polycarbonate) Honeycomb Core: Available in transparent, black, and gray. Common cell sizes include 3.5mm, 6mm, and 8mm. Thickness ranges from 5mm to 500mm, available for customization.

Standard Panel Size: 1220 x 2440 mm. Complimentary cutting services are available.

PP and PC are renowned for their excellent formability and comprehensive properties, making them among the most mainstream raw materials for high-performance honeycomb panels today.

Choosing Qingdao Achieving means partnering with a reliable expert dedicated to turning innovative, lightweight, high-strength, and durable designs into reality, helping you gain a competitive edge in the marketplace.