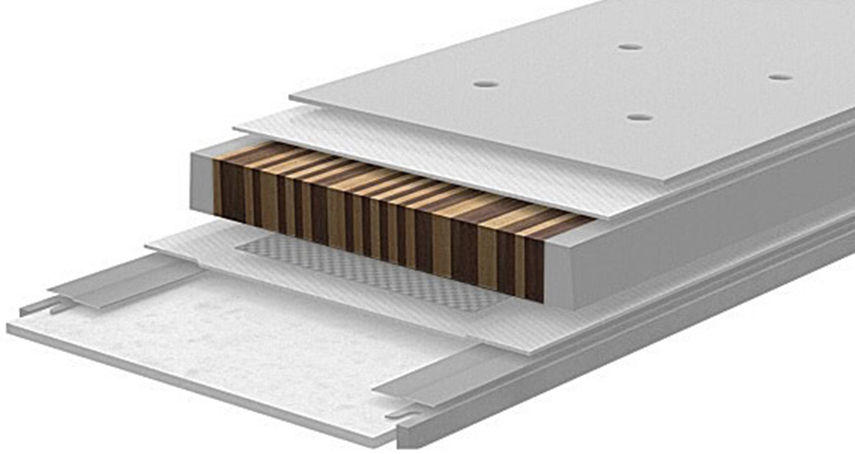

In the continuous evolution of ski gear, material technology has always been at the core. Traditional snowboards are typically made with wood cores, fiberglass, and carbon fiber — materials known for their elasticity, strength, and maneuverability. However, as new materials emerge, polycarbonate honeycomb panels are beginning to catch the attention of snowboard manufacturers.

A polycarbonate honeycomb panel is a lightweight, high-strength, impact-resistant composite material featuring a bio-inspired honeycomb structure. It’s already widely used in aerospace, architecture, and automotive industries. But could it revolutionize the snowboard industry as well?

Theoretically, polycarbonate honeycomb panels offer the following advantages:

Light yet strong: Lighter than traditional wood cores, helping reduce board weight and increase agility.

Impact resistance: Polycarbonate is highly crack-resistant, ideal for high-intensity sports.

Structural stability: The honeycomb design helps disperse impact force and enhances stability while snowboarding.

However, there are challenges too — such as lamination with other materials, performance under extreme cold, and production cost. The material is still in the R&D and testing phase and has yet to become mainstream, though some innovative brands have begun using it in concept models.

We have client who has already used 2mm thickness Polycarbonate honeycomb cores(3.5mm cell size) for experimentation. Preliminary test results show that Snowboard made with PC honeycomb cores shows great signs of improved performance. Whether it is the stability at high-speed skiing or the flexibility during turns, they outperform ski boards made of traditional materials.

As snowboard design trends move toward lighter, stronger, and more sustainable solutions, whether polycarbonate honeycomb panels can enter the market and partially replace traditional materials remains to be seen.