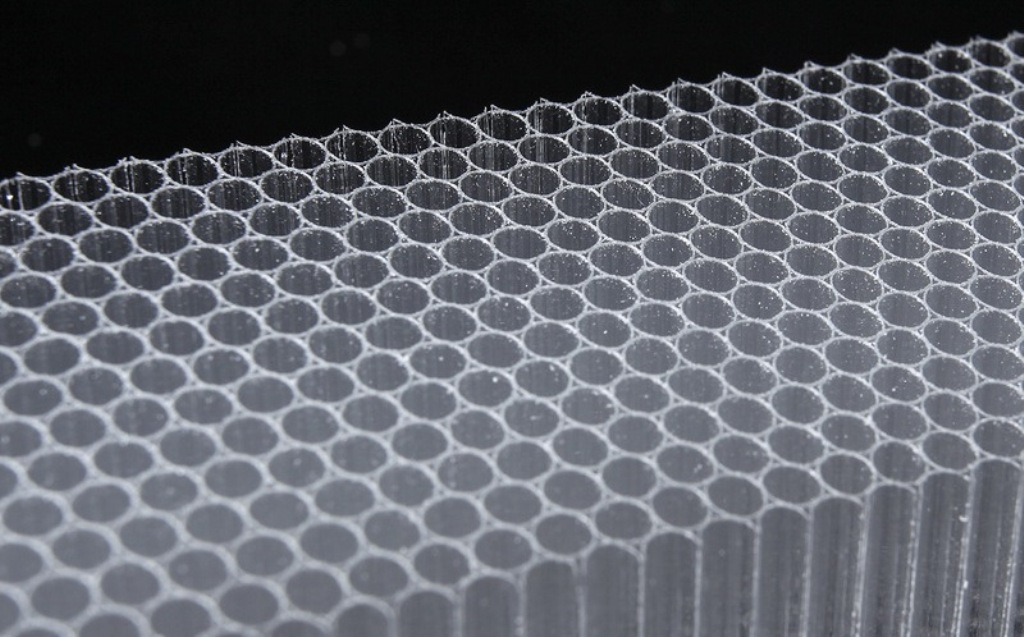

From supermarket refrigeration cases to food processing plants, the round-cell structure is redefining material standards in the food cold chain industry with its unique technical advantages.

Building on the discussion of the technical features and food safety advantages of the round-cell PC honeycomb core from the previous part, this article will analyze in depth the application methods, specific benefits, and future potential of this innovative material in practical cold chain scenarios. Data from actual applications show that refrigerated cabinets using guide plates made of round-cell polycarbonate through-hole honeycomb panels can reduce energy consumption by 15-30%. This improvement in energy efficiency not only reduces operational costs for businesses but also contributes substantially to environmental protection and emission reduction.

Part 04: Application Scenarios & Comprehensive Upgrade of Cold Chain Systems

In the commercial cold chain sector, the round-cell PC honeycomb core is primarily used in air curtain guide systems for open refrigerated and freezer display cases. As an air curtain guide plate, its round-cell structure evenly disperses cold air supplied by the compressor, forming an invisible yet effective temperature barrier. This design allows display cases to maintain an open presentation function while significantly reducing cold air leakage. Compared to traditional solid guide plates, the round-cell honeycomb structure ensures more uniform cold air distribution, eliminating localized "hot spots" and "cold spots," and guaranteeing consistent food storage temperatures. In low-temperature environments where ordinary plastics become brittle, food-grade polycarbonate panels with a round-cell structure maintain excellent impact resistance and dimensional stability even under extreme conditions of -40°C. This makes them suitable for use as dividers and protective materials in frozen logistics. In low-temperature workshops of food processing plants, round-cell PC honeycomb panels can be used as insulating partition wall materials, offering good thermal insulation while meeting sanitary requirements.

Part 05: Efficacy Verification & Dual Returns on Energy Savings and Safety

Practical application data indicates that commercial refrigerated cabinets equipped with round-cell polycarbonate through-hole honeycomb panel guide systems can reduce energy consumption by 15-30% compared to traditional designs. For large supermarket chains, this translates to annual electricity cost savings ranging from tens to hundreds of thousands of currency units. The fluid dynamics advantages of the round-cell structure further enhance cold chain equipment efficiency. The smooth channels reduce cold air flow resistance, allowing the same fan power to produce a more uniform and stable cold air barrier. From an investment return perspective, although the initial cost of food-grade PC honeycomb core is higher than ordinary materials, its energy-saving effects and durability typically result in a payback period of less than two years. In terms of environmental benefits, the improved energy efficiency of cold chain equipment directly reduces carbon emissions.

Part 06: Future Outlook & The Material Basis for Intelligent Cold Chain

With the application of IoT technology in the cold chain sector, performance requirements for cold chain equipment materials are also increasing. The round-cell PC honeycomb core, with its structural stability and material uniformity, provides ideal conditions for accurate temperature sensor measurement, making it an essential material foundation for smart cold chain systems. Under new retail models, cold chain equipment must not only ensure food safety and energy efficiency but also balance aesthetics and brand presentation. The transparent properties and customizable design of polycarbonate through-hole honeycomb panels allow them to meet these diverse needs effectively. In the future, with advancements in materials science and manufacturing processes, the performance of round-cell PC honeycomb cores will further improve, and costs will decrease, promoting their application in broader cold chain scenarios throughout the entire food supply chain.