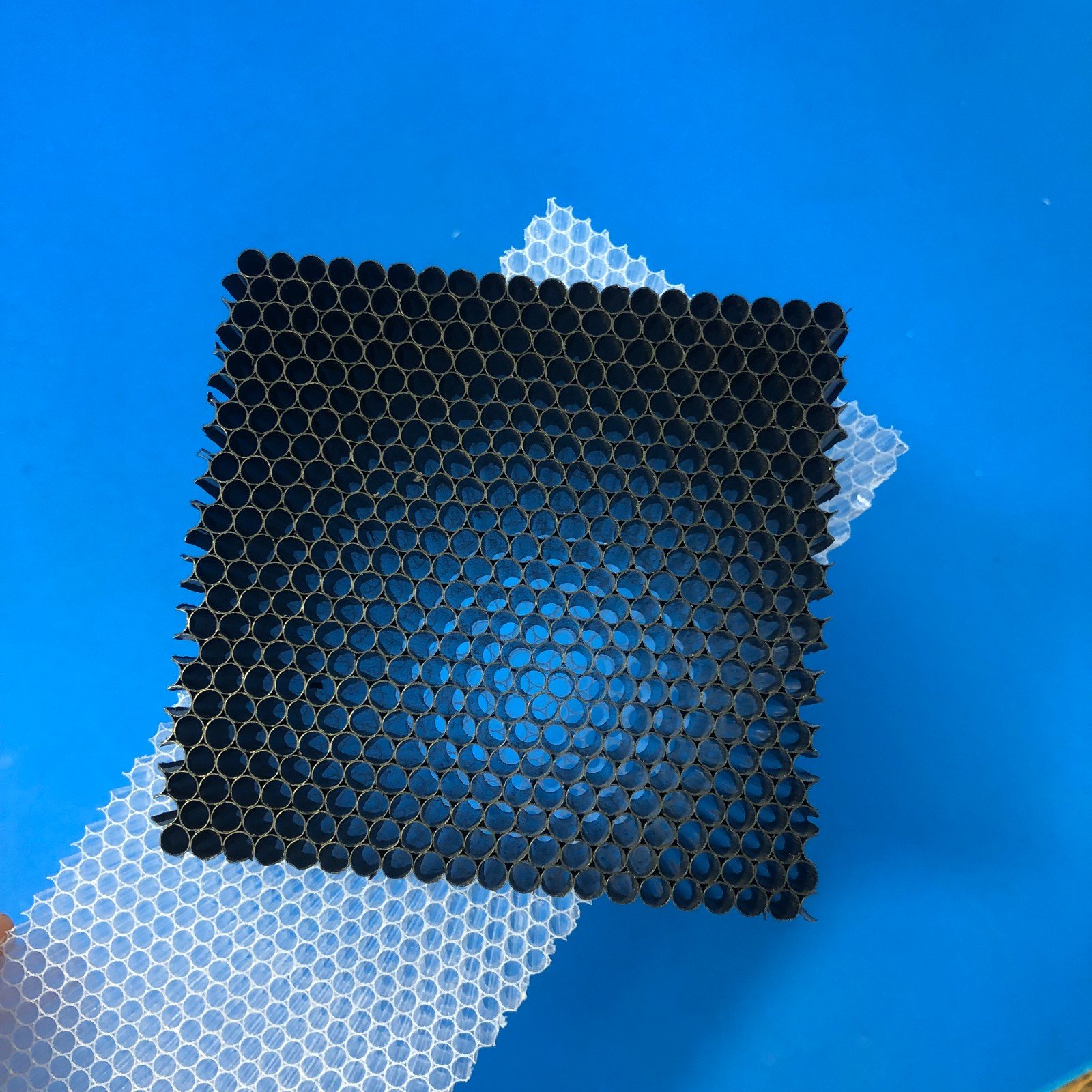

When choosing materials for refrigeration airflow systems, round-cell/circular cell PC(Polycarbonate) honeycomb and hexagonal PVC(Poly Vinyl Chloride) honeycomb are common options, each with unique properties. A comparative analysis of key factors helps determine the better fit for guide strips.

i. Structural Design and Air Guidance Performance.

The round-cell PC(Polycarbonate) honeycomb core features a regular circular cell structure with excellent symmetry. This design allows air to flow smoothly and uniformly, minimising airflow resistance(Decreasing pressure loss by 18-25% at 2m/s airflow) and turbulence, thus achieving stable and efficient air guidance. It ensures that the air curtain evenly covers the display cabinet's outlet, providing an optimal temperature and humidity environment for the items inside.

In contrast, the hexagonal PVC honeycomb core has a hexagonal cell structure. While it can still guide air to some extent, the angular edges may generate turbulence and resistance during airflow, leading to uneven air distribution and affecting the efficiency and stability of air guidance.

ii. Material Properties and Durability

PC (polycarbonate) boasts excellent physical properties such as high strength and toughness, enabling it to withstand impacts and vibrations. It remains deformation-resistant during the long-term operation of display cabinets. Additionally, PC has superior temperature resistance, maintaining stability across a wide temperature range (-40°C to 120°C) to adapt to possible temperature fluctuations inside the cabinet. Its strong anti-ageing properties contribute to a longer service life.

PVC (polyvinyl chloride), however, has relatively lower strength and toughness. In environments with significant temperature changes or vibrations, it is prone to ageing and embrittlement over time, which may compromise the structural stability and air guidance performance of the guide strips.

PC remains flexible at-40°C, while PVC become brittle below-10°C.

iii. Weight and Processability

The round cell PC honeycomb core is lightweight, offering advantages in the installation and transportation of display cabinets by reducing overall weight, lowering installation difficulty, and cutting transportation costs. PC material is also easy to process and form, allowing for the production of guide strips in various shapes and specifications according to different design requirements. It enables high-precision processing with a smooth surface, enhancing both installation quality and aesthetic appeal.

While hexagonal PVC honeycomb core is also processable, its relatively higher density and weight increase processing equipment and technological requirements, potentially raising manufacturing costs.

iv. Environmental Friendliness and Safety

With growing environmental awareness, material sustainability has become a critical consideration. PC is an eco-friendly, recyclable material, causing minimal pollution during production and use.

PVC, on the other hand, may generate harmful substances during manufacturing and is more difficult to recycle, posing potential environmental impacts. In scenarios where display cabinets come into close contact with food, pharmaceuticals, or other sensitive items, environmentally safe materials like PC are clearly preferred.

Conclusion

Through the comprehensive comparison above, the round-cell PC honeycomb core demonstrates significant advantages in air guidance performance, durability, weight, processability, and environmental friendliness, making it a more suitable choice for air curtain outlet guide strips in display cabinets.

Qingdao Achieving Honeycomb Panel Co., Ltd., a professional manufacturer of round-cell honeycomb cores with 20 years of production experience, produces high-quality round-cell PC honeycomb cores using premium new raw materials and manufacturing processes developed with self-developed equipment. Our products undergo strict quality control at every production stage to ensure superior performance and stable quality for air guide strip materials. With years of industry expertise and a professional technical team, we provide customised services to meet diverse customer needs, including customisation of dimensions, thickness, and bevel angles. The standard aperture size is 3.5mm. Choosing our round PC honeycomb core means selecting a high-quality and reliable material for air guide strips.